Custom Aluminum Alloy Solutions for the Die-Casting Industry

At CASS, Inc., we are proud to offer high-quality custom alloy solutions specifically tailored to meet the rigorous demands of the aluminum die-casting industry. Our focus on innovation and eco-conscious manufacturing allows us to stand out as a trusted partner to companies that rely on superior materials to drive their operations forward.

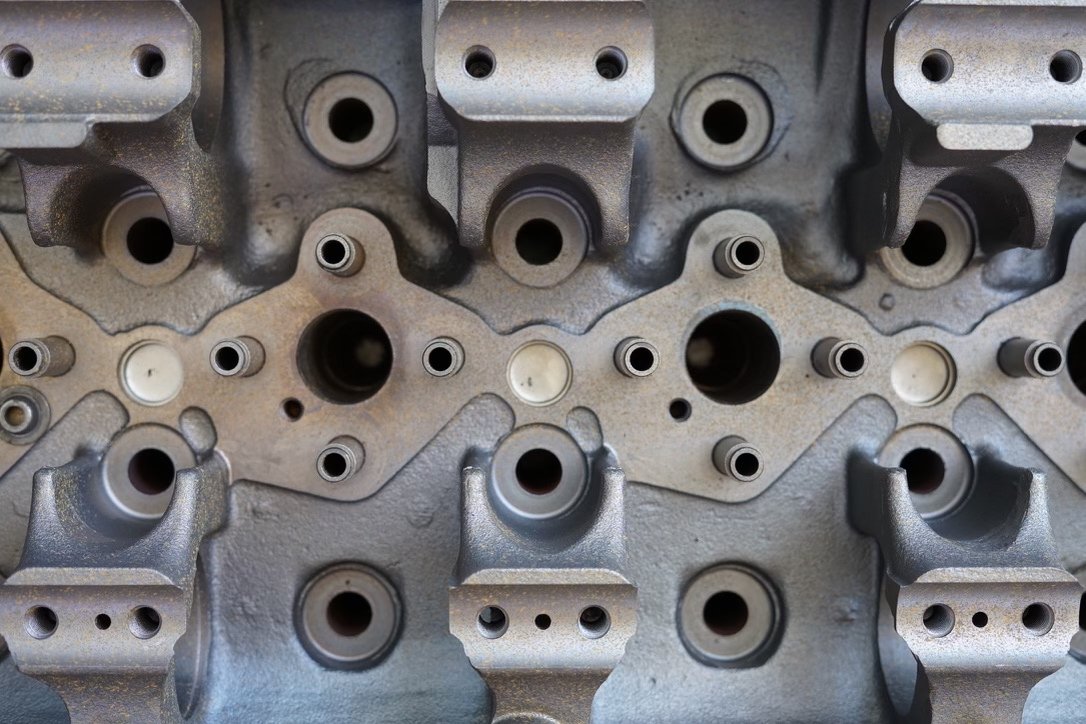

The die-casting industry relies on aluminum alloys that offer the perfect balance of strength, lightness, and moldability. At CASS, we understand these unique requirements, and our custom alloy solutions are engineered to meet the high-pressure conditions and precise tolerances that die-casting demands. Whether it’s for automotive parts, complex components, or industrial applications, our aluminum alloys are designed to enhance both performance and efficiency in the casting process.

But what truly sets us apart is our commitment to sustainability. The environmental impact of primary aluminum production is a growing concern. At CASS, we’re addressing this challenge head-on through our closed-loop recycling process, which allows us to produce premium-grade aluminum alloys with over 90% energy savings compared to creating primary aluminum from raw materials. This not only reduces carbon emissions significantly but also aligns with the growing demand for sustainable solutions in the die-casting industry.

For the die-casting industry, which requires aluminum that can withstand high heat and pressure while maintaining exacting standards, our alloys provide the perfect balance of performance and sustainability. We are committed to pushing the boundaries of what’s possible in die-casting, offering materials that are not only top-tier in quality but also produced with the future of the planet in mind.

Want to explore how CASS’s custom alloy solutions can elevate your die-casting operations while aligning with your sustainability goals?

Contact us today!